The Ultimate Guide to Precision Cutting and Fabrication Techniques: Plasma Cutting, Fiber Laser Cutting, Flame Cutting, and More by Point to Point Metal Industries

In the world of metal fabrication, precision and efficiency are paramount. Advanced cutting technologies have revolutionized the industry, offering a range of methods to suit different materials and applications. In this comprehensive guide, we’ll explore the leading techniques: Plasma Cutting, Fiber Laser Cutting, Flame Cutting, Fiber Laser Engraving & Marking, Metal Fabrication, and Laser Cutting. Each method has its unique advantages and applications, making it essential to understand their distinct characteristics and benefits.

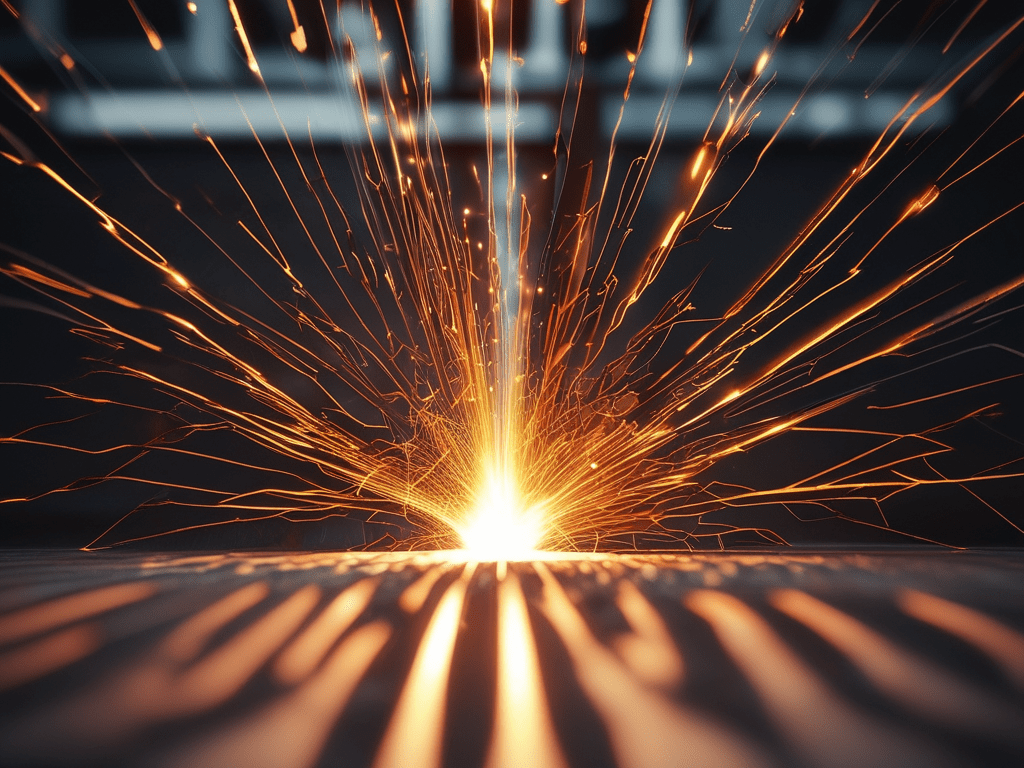

Plasma Cutting

Overview: Plasma cutting is a versatile and efficient method for cutting through electrically conductive materials. It uses a high-velocity jet of ionized gas (plasma) to melt and expel material from the cut.

Benefits:

- Speed and Efficiency: Plasma cutting is exceptionally fast, making it ideal for high-volume production.

- Versatility: Suitable for cutting a variety of metals including steel, stainless steel, aluminum, brass, and copper.

- Precision: Provides clean cuts with minimal dross, reducing the need for secondary finishing.

Applications: Plasma cutting is widely used in automotive repair, industrial construction, and salvage operations, as well as in metal artwork and decorative projects.

Fiber Laser Cutting

Overview: Fiber laser cutting uses a high-powered fiber laser to cut through metal materials with extreme precision. The laser beam is generated by a series of diodes and delivered through a fiber optic cable.

Benefits:

- High Precision: Fiber lasers offer unparalleled accuracy, capable of cutting intricate patterns and fine details.

- Efficiency: Fiber laser cutting is highly efficient, with low power consumption and minimal maintenance requirements.

- Versatility: Effective for cutting a wide range of metals, including steel, aluminum, copper, and brass.

Applications: Fiber laser cutting is ideal for applications requiring high precision, such as electronics, aerospace, and medical device manufacturing.

Flame Cutting

Overview: Flame cutting, also known as oxy-fuel cutting, involves using a torch to heat metal to its ignition temperature and then introducing a stream of oxygen to create a chemical reaction that cuts the metal.

Benefits:

- Cost-Effective: Flame cutting equipment is relatively inexpensive and easy to maintain.

- Thick Material Capability: Capable of cutting very thick materials, making it suitable for heavy-duty applications.

- Portability: Flame cutting torches are portable, allowing for on-site cutting in various locations.

Applications: Flame cutting is commonly used in shipbuilding, construction, and heavy machinery manufacturing, where cutting thick steel plates is required.

Fiber Laser Engraving & Marking

Overview: Fiber laser engraving and marking use a fiber laser to create permanent markings on the surface of materials. This process involves removing or altering the surface layer to create high-contrast marks.

Benefits:

- Durability: Produces permanent, high-contrast marks that are resistant to wear and corrosion.

- Precision: Capable of marking very fine details and small text with high clarity.

- Speed: Fast marking speeds make it suitable for high-volume production environments.

Applications: Fiber laser engraving and marking are used in a wide range of industries, including automotive, aerospace, jewelry, and electronics, for creating serial numbers, barcodes, logos, and intricate designs.

Metal Fabrication

Overview: Metal fabrication encompasses a variety of processes used to shape and assemble metal parts into finished products. This includes cutting, bending, welding, and assembling.

Benefits:

- Customization: Metal fabrication allows for the creation of custom parts and assemblies tailored to specific requirements.

- Strength and Durability: Fabricated metal parts offer high strength and durability, suitable for demanding applications.

- Versatility: Capable of producing a wide range of products, from structural components to intricate assemblies.

Applications: Metal fabrication is essential in industries such as construction, automotive, aerospace, and manufacturing, where customized metal components and structures are required.

Laser Cutting

Overview: Laser cutting uses a focused laser beam to cut through materials with high precision. It is suitable for a variety of materials, including metals, plastics, and wood.

Benefits:

- Precision and Accuracy: Laser cutting offers extremely precise cuts, ideal for intricate designs and fine details.

- Versatility: Capable of cutting a wide range of materials with varying thicknesses.

- Clean Cuts: Produces smooth edges with minimal burring, reducing the need for additional finishing.

Applications: Laser cutting is used in industries such as aerospace, automotive, electronics, and signage, where precision and clean cuts are critical.

Conclusion

Choosing the right cutting and fabrication method depends on the specific requirements of your project, including material type, thickness, precision, and production volume. Whether you need the speed of plasma cutting, the precision of fiber laser cutting, the versatility of flame cutting, or the customization of metal fabrication, understanding these techniques will help you achieve optimal results.

For high-quality, reliable cutting and fabrication services, Point to Point Metal Industries offers expertise and advanced technology to meet all your project needs. Visit www.pointtopointind.com or call +97125506510 to learn more about how we can assist you with your metal cutting and fabrication projects.

Leave a reply to Point To Point Advertising Designs llc Cancel reply